SEPARATION TECHNOLOGY (THAILAND) CO., LTD.

SEPARATION TECHNOLOGY (THAILAND) CO., LTD.

Mechanical separation technology and separation solutions

For more than 60 years Flottweg has been developing and producing high-performance decanter centrifuges, separators, belt presses and plants for solid-liquid separation. Hand in hand with our customers, we are always prepared to meet new challenges and develop goal-oriented solutions. The ultimate goal is always clear: the success of our customers.

Contact

111/79 Soi Rarmintra 40 Nuanchan Bungkoom Bangkok 10230 THAILAND

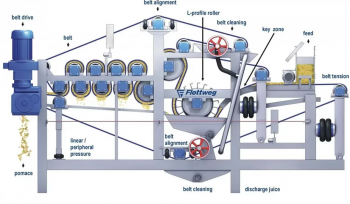

Belt press

Description

High-performance and low maintenance

The belt press is used for dewatering pulp, mash or spent grains silage

Anyone who wants to dewater pomace, mash or spent grains silage uses belt presses. They press the last residue out of the solids cake and are easy to maintain, clean and operate thanks to their easily accessible construction. Flottweg belt presses are robust, durable and powerful - quality made in Germany.

How does the Flottweg belt press work?

A feed roller distributes the mash continuously and evenly on the lower belt. Due to the static pressure, the mash already produces the first juice. The two filter belts are then brought together. The upper belt presses on the mash cake and ensures gentle juicing and a stable mash product cake.

In the pressing area, an L-profile roller dewaters the mash cake. The L-profile roller ensures fast liquid drainage. A large quantities of juice is extracted here. The L-profile roll is followed by press rolls whose diameter decreases with each roller. These press out the mash even further. At the end of the pressing process, optional line pressure rollers and edge zone press rollers may also be used.