SHRED-TECH ASIA CO., LTD.

SHRED-TECH ASIA CO., LTD.

Shred-Tech® has installed over 5,000 Shredding and Recycling Systems worldwide. Our dedicated team of professionals have the experience and expertise to provide efficient and economical solutions to the toughest recycling and shredding problems no matter the location or application challenge.

Contact

https://www.shred-tech.asia/shredding-systems/

789/52 Moo 1, Nong-Kham, Sriracha Chonburi 20230 Thailand

The STQ-100 shredder

Category

Description

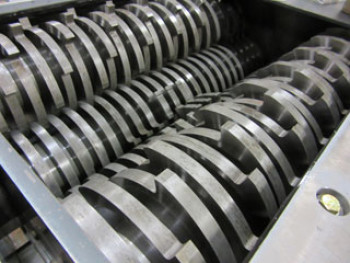

The STQ-100 shredder is designed to process bulk materials including wood, plastics, textiles, electronic equipment, medical waste, organic waste, manufactured products and various other materials, reducing them to a uniform particle size in a single pass.

FEATURES

CUTTING CHAMBER

The STQ line of shredders are available in a wide variety of cutting chamber sizes to meet the demands of various materials in all possible shapes, sizes and material loading methods.

HEX SHAFTS

Shred-Tech's standard durable hex shafts and robust drive systems are at the heart of the STQ line of shredders, ensuring years of reliable service. Engineers have focused a high degree of attention on building a line of four shaft shredders that are maintenance friendly and allow for quick and easy change out of components.

CONSTRUCTION

Heavy-duty construction based around Shred-Tech's standard torsion tube body concept ensures robust trouble free operation. Shred-Tech's proprietary triple seal cutting chamber, abrasion resistant wear components and exceptionally high knife tip cutting force ensure low noise and vibration, reduced wear and decreased maintenance costs.

ROLLOUT

Rollout screens are easily removed from the end of the shredder, allowing for quick and easy screen cleaning and efficient change out of alternate screen sizes.