IWK (Thailand) Limited

IWK (Thailand) Limited

IWK (Thailand) Limited is a wholly owned subsidiary of 125+ year old German Company IWK Verpackungstechnik GmbH.

At IWK, we help customers in pharma, cosmetic & food industry by finding the best packaging solutions to reduce their operation cost up to 50% to achieve quick return of Investment. IWK has blazing track record of assisting Industry to achieve high filling accuracy up to 0.5% & executing quick change-over in less than 15 minutes to stay productive & flexible to meet dynamic market demands.

We offer wide range of solutions meeting basic entry level requirements suitable for small and medium scale companies to high volume mass production machines designed especially for large size manufacturers.

IWK Verpackungstechnik GmbH focuses on the efficient, precise, and attractive packaging of pharmaceutical and cosmetic products.

Contact

333/97 Moo6, Leabklongsongnam Suvarnabhumi Road,Tambol Bangpla, Bangplee/Samutprakarn 10540 Thailand

IWK is known all over the world for:

Tube Filling machine

- 1893 - IWK invented tube filling machines.

- Since 1963 - 16 hours a day, six days a week – Non-Stop. - Oldest IWK machine still in production.

- IWK offers wide range of Tube Fillers with CGMP design for the pharma, personal care & cosmetic industries.

- Cream, Ointment, Gel or Particulates can be filled in variety of tubes shapes, size & filling volumes.

- IWK unique filling system offers flexibility to fill single or multi-colour stripes paste in tube.

- Integrated online check weigher to prevent over or under filling of tube.

Cartoning machine

- 1930 - IWK manufactured first automated cartoning machine.

- Tubes, Bottles, Blisters, Strips, Pouches, Soaps, Multi-packs or Kit (Diagnostic Kit/Hair colour kit) in unit carton.

- Serves entry level speeds from 75 cartons/minute to hi-speed 1000 cartons/minute.

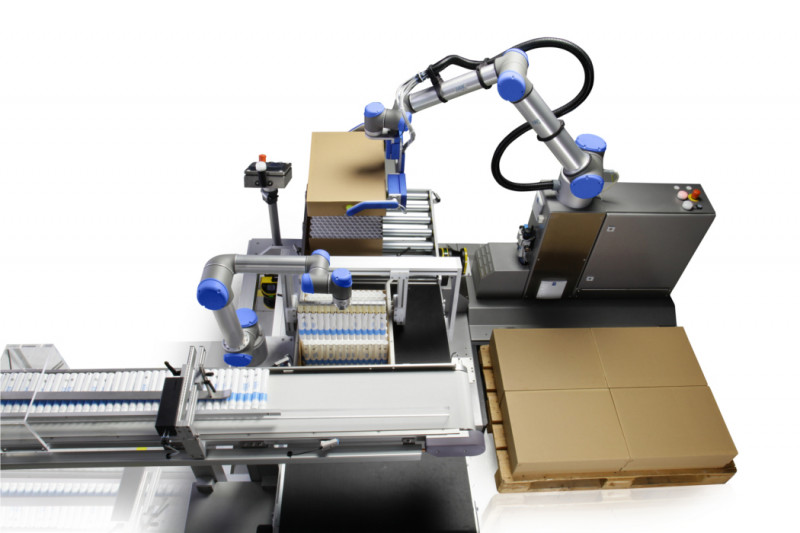

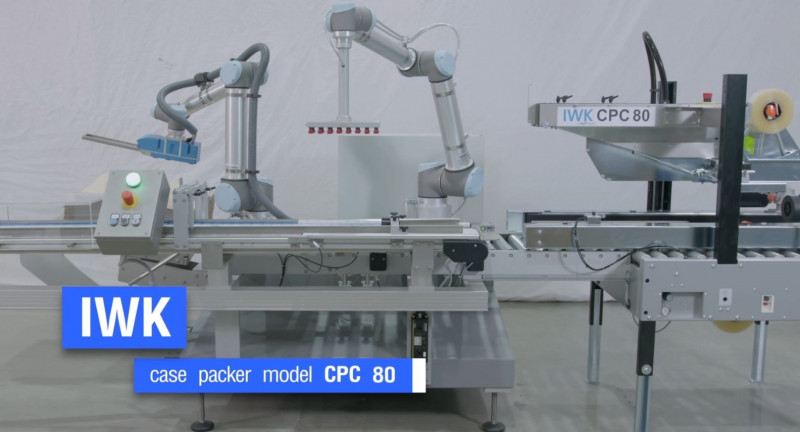

EOL – End of line machines.

IWK is transforming from a machine manufacturer to a fulltime solution provide with next generation equipment’s that are smart, digitally connected, autonomous machines that uses augmented & virtual reality, artificial intelligence (AI) & internet of things (IOT) to measure it performance on the set KPI, calculate OEE and assist you with virtual design review. Cutting edge technology helps you to upgrade from reactive/preventive maintenance to the condition-based maintenance of your factory equipment. Increase the availability of the machines using digital maintenance assistance with transmission of live images provided on the machines using DeBUG Camera, Smart Glasses or Smartphones to prevent unplanned downtime. We are now providing you extended solutions, such as:

- Robot & Cobot based feeders.

- Automatic Case Packers.

- Automatic Palletizers.

- Automatic Depalletizers.

- Automated Guided Vehicles