MESPACK

MESPACK

Headquartered in Barcelona, Spain, Mespack is an international manufacturer of flexible packaging and end of line solutions that engineers and builds high speed machinery for the world's leading consumer packaged goods companies. Recognized as a highly innovative brand delivering creative, functional and sustainable packaging technologies, Mespack has a broad portfolio of products that specialize in forming, filling and sealing sachets, sticks, pouches and other film-based packaging. With more than 2,000 machines in service worldwide, Mespack excels in export management with a sales network in over 70 countries around the world and regional service centers that provide expedited access to parts and service. Mespack serves the food, beverage, pharmaceutical, chemical, confectionary, cosmetic and personal care markets. Mespack is a Duravant Company. For more information, visit www.mespack.com.

Contact

C/ Mar Adriatic 18-Pol. Ind., Torre Del Rector 08130, Santa Perpetua de Mogoda Barcelona 08130 SPAIN

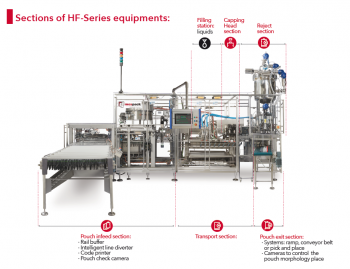

HF-Series fill through the spout with high versatility

Category

Flexible packaging Flexible packaging; plastic Plastic pouch packaging Pouch Pouching Preformed pouch packaging Retort pouch

Description

The new HF series works with top and edge spouted pre-made pouches. Thanks to continuous motion filling through the spout, the headspace is reduced which allows 15% less film by preveting the wave effect. This model is especially thought-out and designed to guarantee the greatest versatility. Thanks to its modular design, the HF series allows the addition of a pouch forming module to replace the automatic rail loading system.There are three models: HF1200.HF2400 and HF-4800. The last two ones can be configured to package different products and formats simultaneously.

The main features of this product are:

- Works with top or corner spouted pre-made pouches

- Intelligent automatic rail loading system

- Possibility of adding HFS (Horizontal Fill and Seal) modeule

- Additional station for laser or inkjet encoders

- Pouch inspection station for vision cameras

- Reduction in headspace for packaging liquid and pasty products

- Continuous dosing system

- You can work with different products and volumes at the same time (2-4 lanes machines)

- Spout cleaning before capping

- Cap cleaning (optional)

- Mespack Athena enabled (HMI and IIoT)

- ATEX compliance (optional)

- Laminar flow (optional)

- Wash down (optional)

- Open frame design: low maintenance and easy access to all areas of the machine

- Easy to operate

- Compact and hygienic design