AMIXON GMBH.

AMIXON GMBH.

amixon® precision mixers and dryers are optimized for processing powders, granules and solid materials. Made in Germany!

amixon® specialises in the development and manufacturing of processing equipment for the processing industry. One focus of the amixon® product range is on sterile equipment which fulfils even the highest requirements in terms of hygiene. Continual innovations such as mixing devices and discharge processes for complete discharge have enabled amixon® to make further improvements in productivity and the hygiene standards of the process equipment. The individual fabricated mixers and dryers find application in many different branches.

For the testing of mixing processes, amixon invites you to visit one of our global test centers. All components of the amixon®-mixers are made in Germany. The production of the machines takes place exclusively in the amixon®-factory in Paderborn, Germany.

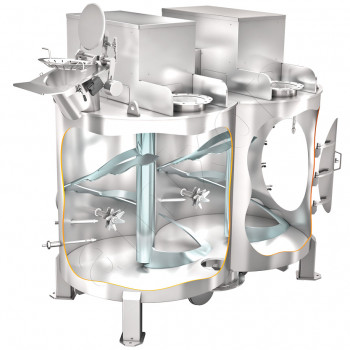

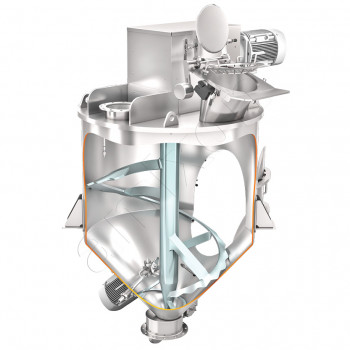

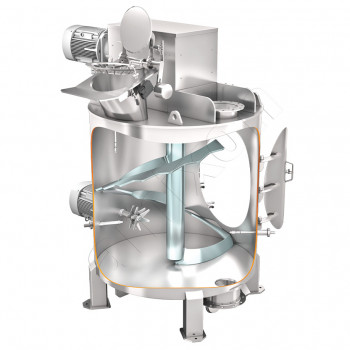

amixon® twin-shaft mixer HM

Description

amixon® mixers achieve technically ideal mixing qualities that can't be further improved.

One and the same mixer can homogenize extremely gently, but also deagglomerate intensively.

The degree of discharge is up to 99.99%.

Ideal mixing qualities and excellent particle protection are guaranteed in the twin-shaft mixer. The amixon® twin shaft mixer creates a three-dimensional product flow which guarantees optimum mixing quality and gentle particle handling. The mixing container consists of two cylinders that merge into each other. In their centre there are two helical mixing tools rotating in the same direction. The helices have a progressive pitch. The width of the helical blade is dimensioned such that a fifth of the entire mixing material is redistributed with one revolution of the mixing tool. The gentle upward transport of the mixture takes place by means of the helical blade mixing tools, while the downward flow takes place naturally due to the effect of gravity.