AMIXON GMBH.

AMIXON GMBH.

amixon® precision mixers and dryers are optimized for processing powders, granules and solid materials. Made in Germany!

amixon® specialises in the development and manufacturing of processing equipment for the processing industry. One focus of the amixon® product range is on sterile equipment which fulfils even the highest requirements in terms of hygiene. Continual innovations such as mixing devices and discharge processes for complete discharge have enabled amixon® to make further improvements in productivity and the hygiene standards of the process equipment. The individual fabricated mixers and dryers find application in many different branches.

For the testing of mixing processes, amixon invites you to visit one of our global test centers. All components of the amixon®-mixers are made in Germany. The production of the machines takes place exclusively in the amixon®-factory in Paderborn, Germany.

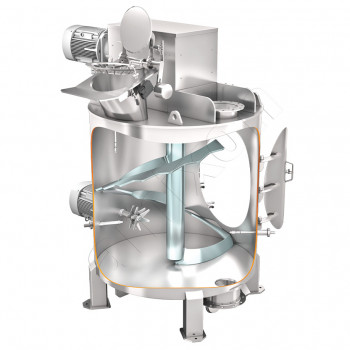

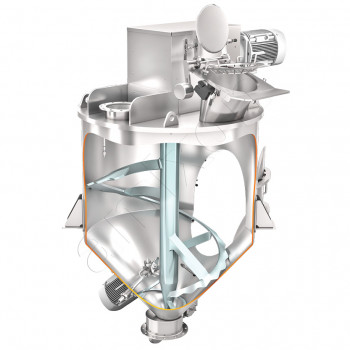

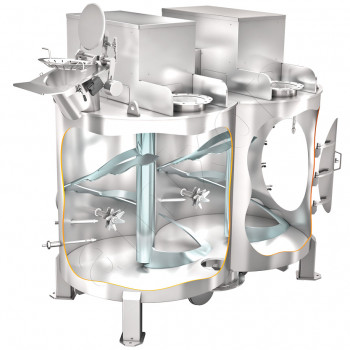

amixon® Powder mixer VM

Description

Ideal mixing quality at low rotational frequency

An ideal mixing quality is guaranteed in the amixon® mixer by three dimensional flow without dead space.

The mixing tool is only supported and driven at the top.

Complete discharge is possible with patented SinConvex® and ComDisc® technology.

Ideal mixing is guaranteed by the dead space free flow. The central mixing tool is mounted and driven only at the top. The helical blade gathers the mixing goods at the periphery of the mixing chamber and transports them upwards. Once at the top, the mixed material flows downward in the center of the vessel. The goods are ideally mixed at low rotational frequency, regardless of differing particle sizes, bulk densities and flow properties. In addition, the degree of filling of the mixers can vary from approx. 10% to 100%. One and the same mixer can be used for extremely gentle homogenization, but also for intensive deagglomeration with extremely high energy input. After only about 40 to 160 mixer revolutions, technically ideal mixing qualities are produced that cannot be improved in practice. The patented ComDisc® system enables virtually residue-free deagglomeration of up to 99.99%.

amixon® apparatuses comply with current hygiene guidelines. They are manufactured in compliance with EHEDG, GMP and FDA regulations. Made in Germany!