RHEON AUTOMATIC MACHINERY CO., LTD

RHEON AUTOMATIC MACHINERY CO., LTD

The company name, "RHEON" was derived from the concept of Rheology. In the several thousand year history of mankind, man has shaped food in the palm of his hand, hence creating and shaping much of the priceless culture which exists today.The shaping of these foods not only created an art form, but also originated many delicious tastes.

Rheon Automatic Machinery has been developing, manufacturing and supplying a wide range of

high quality food processing machines, and factory systems around the world.

We are the world’s first developer of fully automated croissant production line and automatic encrusted (filled) product machine.

Our machines have been exported to over 125 nations and our technology plays a role in automated ethnic foods production around the world.

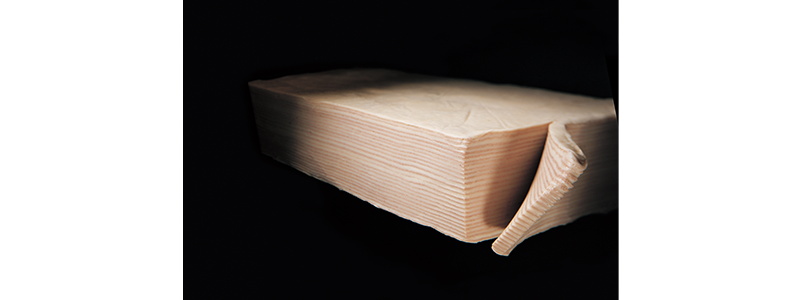

Rheon's applied rheological engineering offers the new "Stress Free® System" to create damage-free dough during the forming process.

Rheon strongly supports preserving priceless cultures of various countries by improving labor conditions and enhancing the valuable meaning behind each culture. Rheon would like to emphasize that the purpose in automating bread production is not only to facilitate the entire production procedure.

If the steps taken to automate the production have any flaws, the original taste and shape of each product will be sacrificed. This will cause the culture to lose its genuine aspects, and the traditional food culture will eventually disappear.

To ensure that these problems are prevented, Rheon has developed the system, "From Dough Sheet to Bread". Bread dough is conventionally formed by dividing a large dough block into small portions, and forming round, bar, or flat shapes.

However, this process applies stress to the dough during the dividing process, greatly damaging the gel and cell structures. The dough will not be able to produce air bubbles, resulting in poor-quality bread. Therefore, it has been essential to use some chemical additives for strengthening the dough structure, and to undertake extra processing to recover the damaged dough structure after dividing.

Rheon has made it possible to eliminate this time-consuming process by forming continuous thin dough sheets prior to the dividing process. While forming the dough into thin layers, the dough binding is strengthened to create any form of bread product. This is the "Stress Free® System".