AMIXON GMBH.

AMIXON GMBH.

amixon® precision mixers and dryers are optimized for processing powders, granules and solid materials. Made in Germany!

amixon® specialises in the development and manufacturing of processing equipment for the processing industry. One focus of the amixon® product range is on sterile equipment which fulfils even the highest requirements in terms of hygiene. Continual innovations such as mixing devices and discharge processes for complete discharge have enabled amixon® to make further improvements in productivity and the hygiene standards of the process equipment. The individual fabricated mixers and dryers find application in many different branches.

For the testing of mixing processes, amixon invites you to visit one of our global test centers. All components of the amixon®-mixers are made in Germany. The production of the machines takes place exclusively in the amixon®-factory in Paderborn, Germany.

amixon® powder mixers and dryers are tailor-made solutions manufactured according to the customer’s requirements. All machines as well as the components are exclusively made in Germany. Among others, one of the main fields of application is the food industry. amixon® machines are used to process instant soups and sauces, aroma, spices, bakery ingredients and premixes, baby formula, dietary supplements, instant powder for beverages and many more.

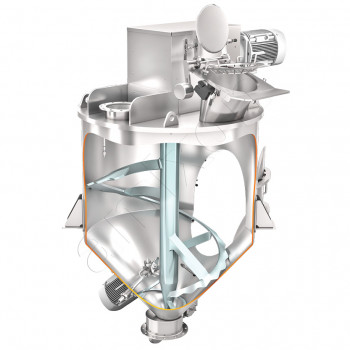

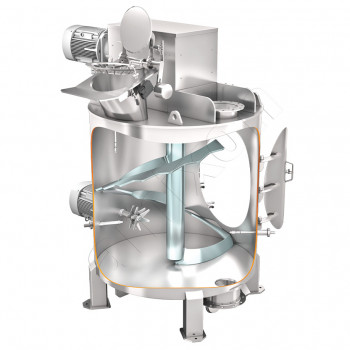

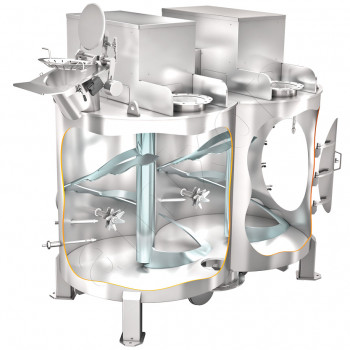

One of the benefits of amixon mixers is that ideal mixing quality can be achieved when the mixer is filled to a level anywhere between 10 % and 100 %. The mixing process proceeds without creating any inactive regions, since the patented SinConvex® mixing device, which takes the form of a helical spring, drives the materials upwards at the periphery of the mixing chamber and then allows it to flow downwards in the centre. Because individual components, such as spray-dried agglomerates, have to be handled very gentle, the velocity at the circumference is barely 1 m/s. Ideal mixing quality is achieved within a mixing time of between 3 and 6 minutes.

When it comes to the discharge of the mixing goods, the new ComDisc®-system provides a carry out of up to 99,997% and more. At the conclusion of each mixing process an automatic washing-in-place operation takes place by means of the patented WaterDragon®-system.

Because of the seamless detail design of all components, the machine can guarantee a high standard of hygiene for little personal effort. It is considered to be microbiologically controllable and conforms with GMP as well as being FDA-certified for the production of pharmaceutical goods and bacterial cultures. Manhole openings, nozzles and flanges are designed in accordance with EHEDG recommendations, and are manufactured using the company's own CleverCut® fabrication process.